With over 40 years’ trading in the vac forming industry, our team of experts will design and manufacture any vacuum formed packaging you need to help you get your project to market.

GVF Packaging is serious about sustainability too – over 90% of the packaging we supply is made from recycled materials which can then go on to be recycled again.

Known for our personal service, quality packaging, and speed to market, we offer a complete service for all your vacuum forming needs.

Our eight innovative inline fast cycling thermo-former machines operate 24 hours a day, and our vast range of stock materials means we can colour match and cater for both small and large volume orders with a quick turnaround.

A trusted packaging partner for international household brands you can rest assured that you’re in safe hands with GVF Packaging.

WHY CHOOSE VACUUM FORMING?

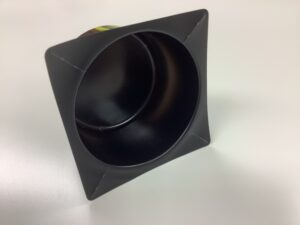

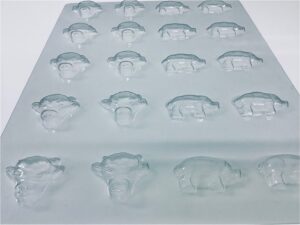

Vacuum forming is a really cost-effective packaging solution and is ideal if you need a custom insert that fits perfectly around your product.

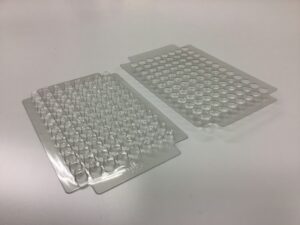

A popular choice of packaging for all sectors (including cosmetics, gifts, sport, food, automotive and healthcare), vacuum forming packaging keeps products firmly in place and displays them attractively.

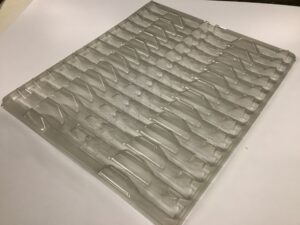

Vac formed plastic trays and inserts can also be designed to be stackable for ease of shipping and storage.

Here are some popular applications of vacuum forming:

- Retail gifts

- Box insert – Perfectly displays and secures your product in place

- Food trays

- Transit trays – Reduces product damages

- Clamshell/Clampack – A great way to showcase your product.

- Heat-sealed blisters

- Sheet forming – Ideal for larger and thicker gauge material

And remember, if your vac forming needs a packaging friend to complete your shelf-ready pack then we can also help with that too.

Please feel free to contact us for any packaging requirements you may have – sales@gvf.co.uk.